Home > PRODUCT > CERAMIC SAND BLASTING BEADS

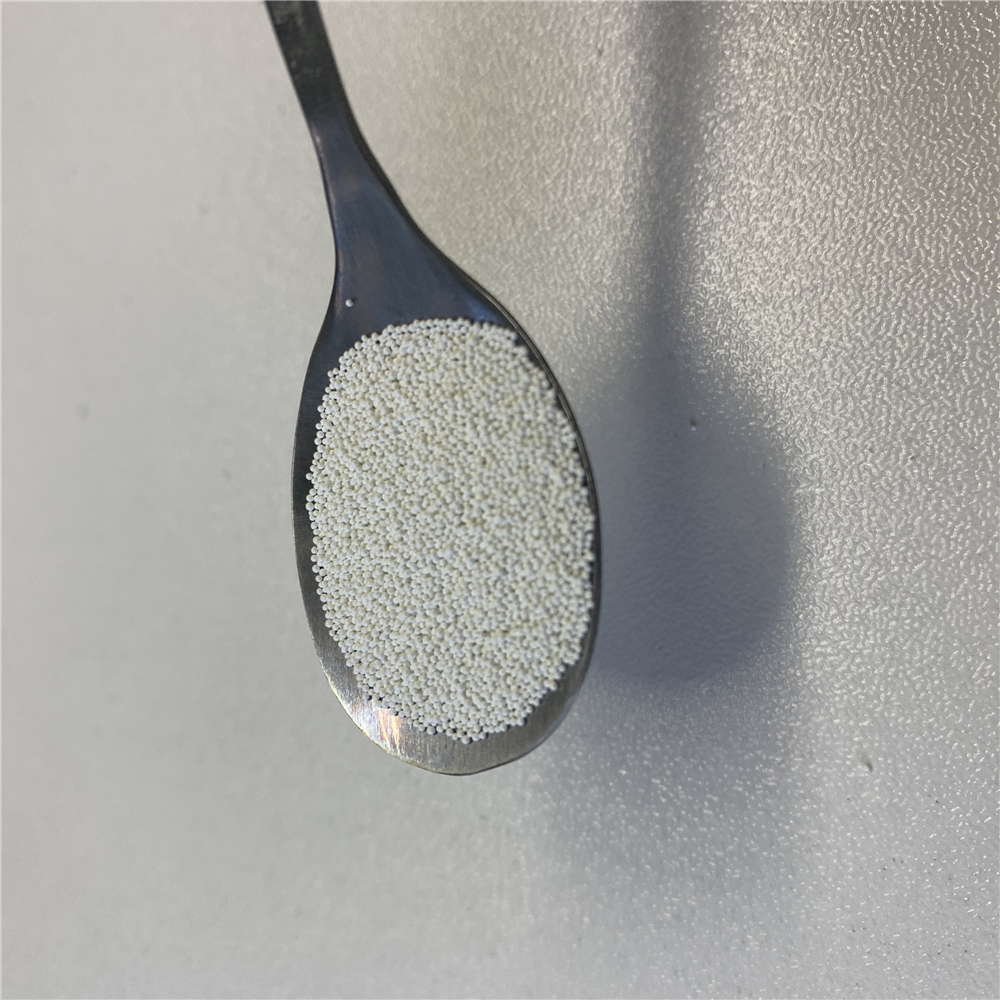

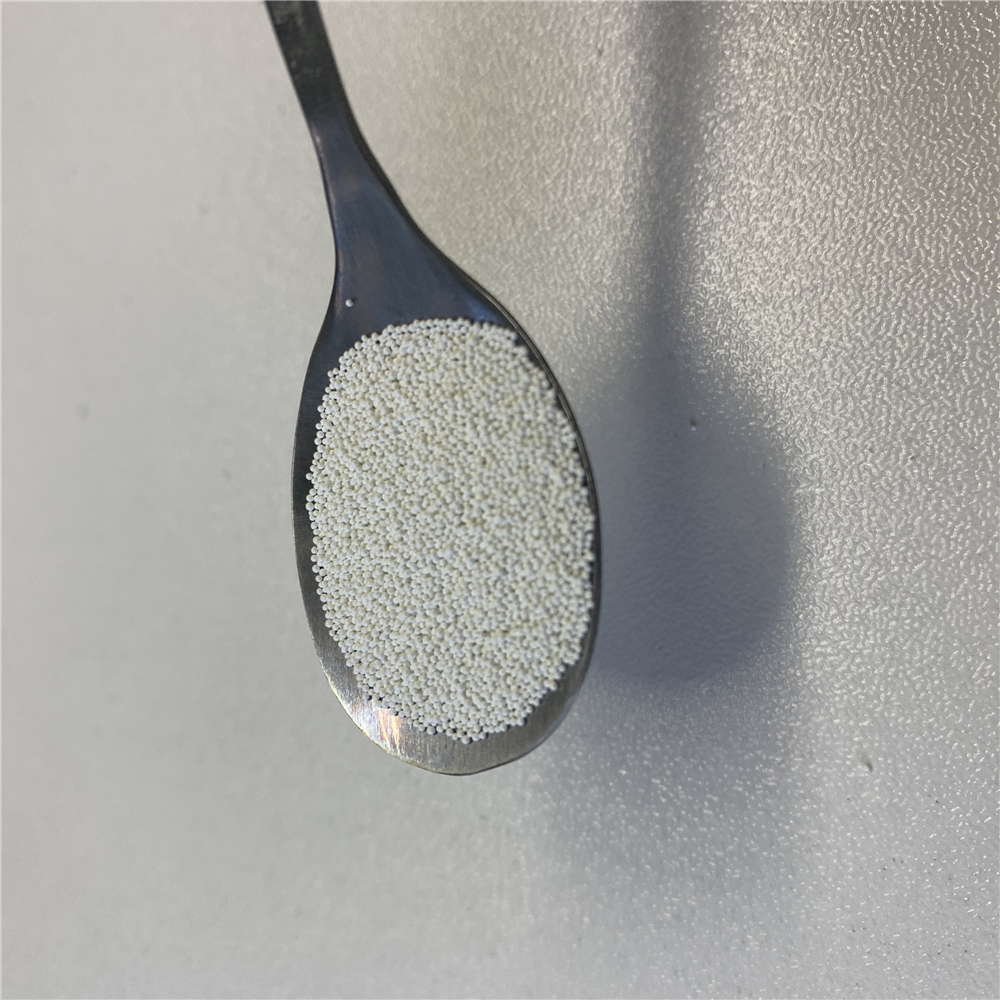

zirconia ceramic shot Z300 Strengthening aviation shot peening Z300 Z600 aircraft engine blade coating

Ceramic Peening Beads Aerospace Peening zirconia ceramic shot Z300 Strengthening aviation shot peening Z300 Z600 aircraft engine blade coating

- Email:zzhaixu@163.com

- Tel: 8615838373120

- PRODUCTS

- SG ABRASIVES

- Fused Zirconia Plasma Powder

- ALUMINA BALL

- Fused Yttirum Plasma Powder

- CERAMIC SAND BLASTING BEADS

- WHITE FUSED ALUMINA

- BROWN FUSED ALUMINA

- PINK FUSED ALUMINA

- ZIRCONIA FUSED ALUMINA

- BLACK SILICON CARBIDE

- Chromite sand/powder/flour

- GARNET SAND/MICROPOWDER

- BORON CARBIDE

- CERAMIC FOUNDRY SAND

- TABULAR ALUMINA

- GLASS BEADS

- ZIRCON SAND

- GREEN SILICON CARBIDE

hot PRODUCT

CONTACT US

- Sunshine Ma

- zzhaixu@163.com

- +86-15838373120

- Sunshinema90

Properties

zirconia ceramic shot Z300 Strengthening aviation shot peening Z300 Z600 aircraft engine blade coating

|

ITEM |

UNIT |

TYPICAL DATA |

|

ZRO2 |

% |

65 |

|

SIO2 |

% |

30 |

|

other |

% |

5 |

|

tetragonal phase ZRO2 |

% |

68 |

|

glass phase |

% |

32 |

|

true density |

G/CM3 |

3.86 |

|

moh's hardness |

MOHS |

7.5 |

Advanced Ceramic Peening Beads-Aerospace Peening

|

SIZE |

UNIT |

DIAMETER RANGE |

|

Z150 |

μm |

150-212 |

|

Z210 |

μm |

210-300 |

|

Z300 |

μm |

300-425 |

|

Z425 |

μm |

425-600 |

|

Z600 |

μm |

600-850 |

|

Z850 |

μm |

850-1180 |

This series of products is produced according to the American AMS2431/7B standard and has a wide range of applications, especially in high-tech fields such as the automotive industry, aerospace and nuclear industry, and military fields such as aircraft turbine blades, shafts and other precision parts, surface treatment of weapons and equipment, surface treatment and strengthening of various spring wheel hydraulic parts, and removal of material internal stress.

Main advantages of the product

Good sphericity, good surface treatment effect, good consistency of batch production

High toughness, high hardness, high wear resistance, and recyclable

Compared with traditional abrasives such as steel sand, it will not cause pollution to the product

Application

Ceramic Peening Beads Aerospace Peening zirconia ceramic shot Z300 Strengthening aviation shot peening Z300 Z600 aircraft engine blade coating

Inquiry

- Contact: Sunshine Ma

- Email: zzhaixu@163.com

- WhatsApp: +86-15838373120

- Skype: Sunshinema90

- Tel: +86-15838373120

- Fax: +86-371-60305637

Get in touch

If you have any questions, feedback or comments,

please fill out the form below and we will reply you back as soon as possible.

LEAVE A MESSAGE

Please enter your question and contact information.we will get back to you as soon as possible!