- PRODUCT

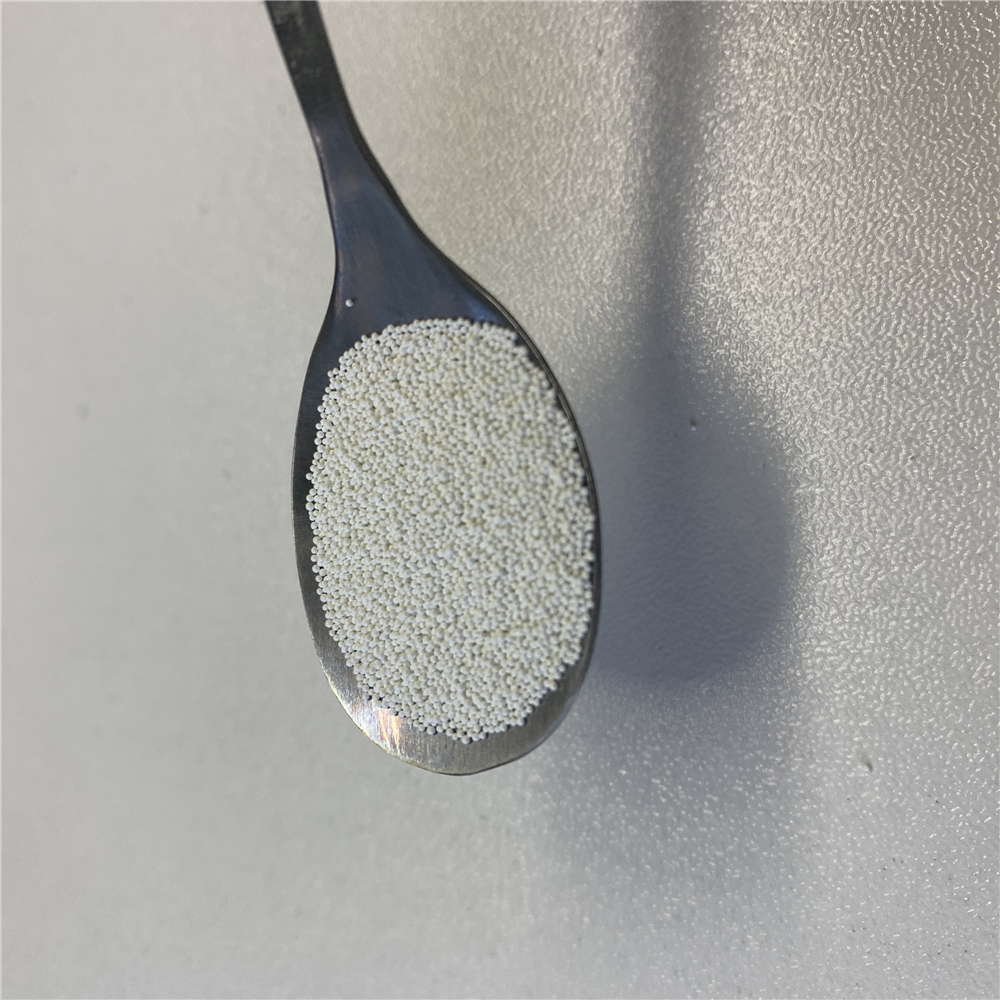

- CERAMIC SAND BLASTING BEADS

- SG ABRASIVES

- Fused Zirconia Plasma Powder

- ALUMINA BALL

- Fused Yttirum Plasma Powder

- WHITE FUSED ALUMINA

- BROWN FUSED ALUMINA

- PINK FUSED ALUMINA

- ZIRCONIA FUSED ALUMINA

- BLACK SILICON CARBIDE

- Chromite sand/powder/flour

- GARNET SAND/MICROPOWDER

- BORON CARBIDE

- CERAMIC FOUNDRY SAND

- TABULAR ALUMINA

- GLASS BEADS

- ZIRCON SAND

- GREEN SILICON CARBIDE

hot PRODUCT

CONTACT US

- Sunshine Ma

- zzhaixu@163.com

- +86-15838373120

- Sunshinema90

PRODUCTS List

CERAMIC SAND BLASTING BEADS

SG ABRASIVES

Fused Zirconia Plasma Powder

ALUMINA BALL

Fused Yttirum Plasma Powder

WHITE FUSED ALUMINA

BROWN FUSED ALUMINA

PINK FUSED ALUMINA

ZIRCONIA FUSED ALUMINA

BLACK SILICON CARBIDE

Chromite sand/powder/flour

GARNET SAND/MICROPOWDER

BORON CARBIDE

CERAMIC FOUNDRY SAND

TABULAR ALUMINA

GLASS BEADS

ZIRCON SAND

GREEN SILICON CARBIDE

PRODUCT

White Fused Alumina

White fused alumina was made from the high quality alumina by melting above 2000 in the electric arc furnace and cooling.

Ceramic Foundry sand

Ceramic Foundry sand is a kind of refractory particle with diameter of 0.053-2.0mm.Mainly made of Al2O3·SiO2. It is ball-shaped particle made from bauxite,by high-temperature melting in electric-arc furnace, spraying and cooling.

Glass Beads

Glass Beads are made of hardened spherical soda lime glass and are a multi-faceted and commonly used media. Cost effective, ideal where metal contamination is not allowed, and often used to peen difficult to reach part areas.

zirconia ceramic shot Z30...

zirconia ceramic shot Z300 Strengthening aviation shot peening Z300 Z600 aircraft engine blade coating ITEM UNIT TYPICAL DATA ZRO2 % 65 SIO2 % 30 other % 5 tetragonal phase ZRO2 % 68 glass phase % 32 true density G/CM3 3.86 moh’s hardness MOHS 7.5 Advanced Ceramic Peening Beads-Aerospace Peening SIZE UNIT DIAMETER RANGE Z150 μm 150-212 Z210 μm 210-300 Z300 μm 300-425 Z425 μm 425-600 Z600 μm 600-850 Z850 μm 850-1180 This series of products is produced according to the American AMS2431/7B standard and has a wide range of applications, especially in high-tech fields such as the automotive industry, aerospace and nuclear industry, and military fields such as aircraft turbine blades, shafts and other precision parts, surface treatment of weapons and equipment, surface treatment and strengthening of various spring wheel hydraulic parts, and removal of material internal stress. Main advantages of the product Good sphericity, good surface treatment effect, good consistency of batch production High toughness, high hardness, high wear resistance, and recyclable Compared with traditional abrasives such as steel sand, it will not cause pollution to the product

SG abrasives sand F8-F220...

SG abrasives sand F8-F220 F230-F1200 WHITE COLOUR BLUE COLOUR Sol-gel Alumina abrasive grain Ceramic Alumina grit SG Abrasive grain SG(Sol-gel) is the ceramic alumina abrasive developed and produced by our company. It’s a composition of sub-micro aluminum oxide and lamellar grain containing rare earth materials. The grain combines unique self-sharpening properties with high hardness and toughness. Ceramic alumina is applied to kinds of bonded abrasive tools with moderate bulk density and nice particle shape. Ceramic Alumina can be used in a wide range of applications and provides the highest performance and a long tool life. Product Advantages Sol-gel Alumina abrasive grain Ceramic Alumina grit SG Abrasive grain Features: 1. Small crystal size about 100-150nm, which is even much smaller than zirconia alumina. And it’s hundredths of the size of normal fused alumina grains.So it will make abrasive wheels increase lifetime by several times than ordinary wheels. 2. Excellent self-sharpening performance. The sol-gel grain will get new grinding edges after grinding. The edges are get from the single grain crystal instead of off a whole crystal. That makes the grain much sharper than normal fused alumina. 3. The microscopic hardness of sol-gel alumina is about 1900-2400 kgs/cm2,which is higher than...

Fused Yttrium Plasma Powd...

Fused Yttrium Plasma Powder Fused Yttirum Plasma Powder is made from Rare-Earth Yttium oxide. It features with high purity, well-developed crystal extremely high thermal resistance, high thermal conductivity, tiny thermal expansion rate and good penetration resistance. It is an ideal material in plasma coating material in Aeronautics and Astronautics and electronic ceramic, etc. Physical index: Melting point (℃) 2410 Ture Density(g/cm3) 5.05 The specifications of fused Yttrium plasma powder: Fused Yttrium Powder Chemical composition(%) Y2O3 SiO2 Al2O3 Fe2O3 TiO2 ≥99.5 ≤0.05 ≤0.02 ≤0.05 ≤0.2 High purity Yttrium oxide microsphere Chemical composition(ppm) Y2O3 Fe Na Mg Al Si K Ca ≥99.9% <10 <1 <2 <1 <10 <20 <8 Available Sizes: 200F, 325F, 1000F, etc. (Customized sizes are available upon request) Applications: Kiln Furniture Ceramic setters thermal spraying. Electromagnetic graphite burning plate coating. Semiconductor Etching equipment Plasma coating. CVD、ESC(Electrostatic chunk) equipment plasma coating.

LEAVE A MESSAGE

Please enter your question and contact information.we will get back to you as soon as possible!